It is widely used in metallurgy, building materials, chemical industry, mining, highway construction, water conservancy and hydropower and other industries.

Applications: Stone crusher is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate etc. Different final output size could meet your different needs.

+86-13781250944*24-hourWhatsapp/Wechat

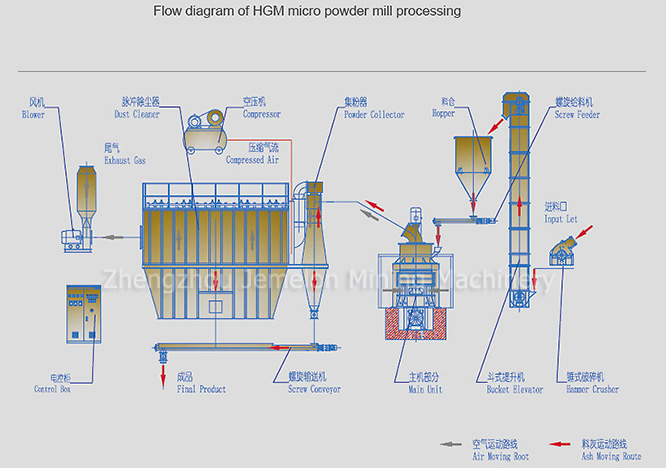

HGM series of three-rings and medium-speed micro powder grinder is a new type of making micro powder machines through more than twenties times research and improvement

Unique design and various product sizesIn the grinding chamber of the machine, a 1500kg~2000kg compressing device is designed and installed on the upper part of the star rack, which increases the grinding force imposed on the material to 800~1500kgf, the finest finished product to 1000 mesh and the production consumes the same power by 10- 30%.

Environmentally friendlyThe dust removal effect of the high pressure suspension mill meets the national standard of dust control.

TightnessThe adoption of multi- stage sealing and premium processing technique keeps the grinding equipment closed tightly, which lengthens its service life.

Low operating costThe wearing parts are made from premium materials. This improvement makes the equipment perform longer and reduces the cost of the clients.

Improved utilization rateWhen the wearing between the grinder roll and the grinding ring enlarges to a certain extent, the length of high pressure spring can be adjusted to keep the constant grinding force between the grinder roll and the grinding ring, which ensures stable layout and fineness.

HGM series three-ring ultra-fine mill is the world leading grinding equipment which adapts the Swedish advanced milling technology and is especially designed for processing ultra-fine powder or grinding any non-flammable and non-explosive materials such as quartz, feldspar, calcite, limestone, talc, ceramics, marble, granite, dolomite, bauxite, iron ores, barite, bentonite, calcium, kaolin, plater, mica, graphite, etc. The size of the finished product can be adjusted between 325-3250mesh.

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 | |

| Average Diameter(mm) | 800 | 930 | 1035 | 1300 | ||

| NO. | Ring of Roller | 3 | 3~4 | 3 | 4 | 4 |

| roller | 21 | 24~32 | 27 | 34~36 | 40~44 | |

| Main Shaft Speed(r.p.m.) | 230~240 | 200~220 | 180~200 | 135~155 | ||

| Feeding Size(mm) | ≦20 | |||||

| Output Size | μm | 5~47 | ||||

| mesh | 2500~325 | |||||

| Capacity (t/H) | 500~4500 | 600~6500 | 700~7000 | 1000-8500 | 1500-12000 | |

| Motor Power(kw) | Main Engine | 55-75 | 2×37-2×45 | 110 | 110-132 | 160-185 |

| Air Bolwer | 18.5 | 22 | 37 | 37 | 45 | |

| Powder Collector | 45 | 55 | 75 | 75 | 2-55 | |

| Crusher | 11 | 11-18.5 | 18.5 | 18.5 | 18.5-45 | |

| Bucket Elevator | 3 | 3 | 3 | 4 | 4 | |

| Spiral Conveyor | 3 | 3 | 3 | 3 | 2-4 | |

| Discharge Valve | 2×0.75 | 2×0.75 | 3×0.75 | 2×0.75-1×1.1 | 4×1.1 | |

| Air Compressor | 7.5 | 15 | 15 | 15-22 | l | |

| Dimension(L×W×H)(m) | 10×2×5.5 | 11.9×2.7×5.8 | 14.5×3.8×6.3 | 14.5×3.8×6.3 | 14.5×3.8×6.3 | |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13781250944*24-hourWhatsapp/Wechat