C European jaw crusher is widely used in mining, building materials, cement, metallurgy, road construction, chemical industry raw materials and other fields, especially suitable for crushing medium hardness materials, such as rock, ore and so on.

Applications: various mineral ores and rocks which anti-pressure do not exceed 320Mpa.

+86-18638682051*24-hourWhatsapp/Wechat

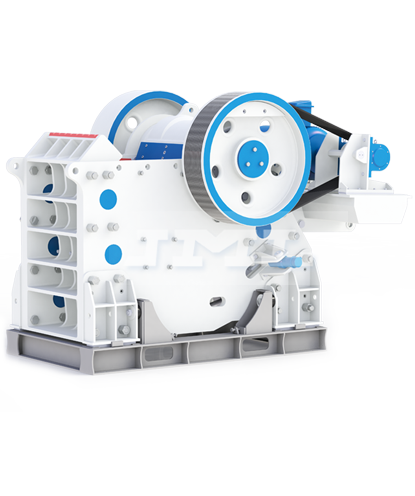

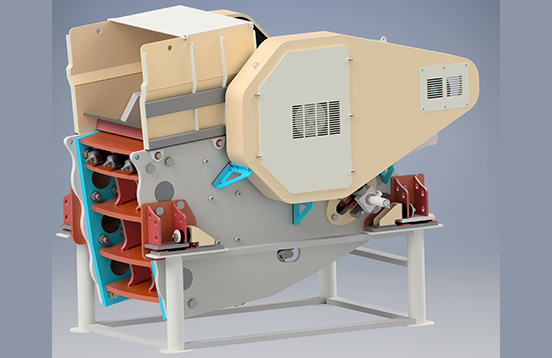

The C series European jaw crusher is a new generation of high-efficiency jaw crusher developed by Zhengzhou Jemelon Mining Machinery Co., ltd. based on the advanced foreign design and our decades of experience in the crushing industry. This series of European jaw crusher has made great progress in structural design, production material selection, process improvement and other aspects, providing a solid technical foundation for efficient production, high structural strength and high stability of the equipment. As the preferred model for the new generation of hard and highly abrasive rocks and minerals, the C series European jaw crusher can provide modular supply solutions according to different working conditions of customers' on-site production to meet the production needs under various conditions.

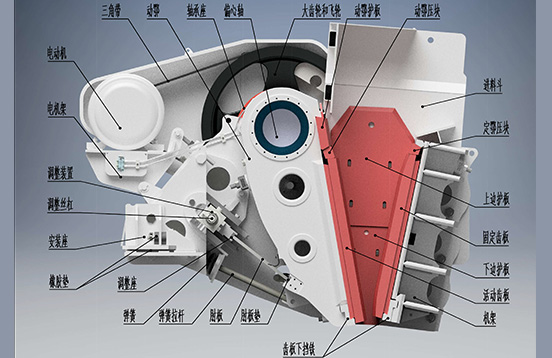

The fuselage adopts non-welded frame structure with high strength wall panel and finished pin to form a firm frame, which improves the load tolerance.

The movable jaw assembly, belt wheel and flywheel are all made of high-quality cast steel or cast iron for exceptional durability. In addition, the series uses high-strength cast eccentric shafts and High quality bearing for unparalleled reliability.

The C-series European jaw crusher has optimized cavity design, feed port size and chamber height is highly coordinated, feed port length to width ratio through strict testing, can maximize avoid the phenomenon of clog.

The Strictly abide by the kinematic performance design, the use of large centrifugal force and steep elbow bevel design, so that the effective stroke at the bottom of the crushing chamber is larger, to ensure that the equipment has strong power.

The discharge opening adjustment device adopts double wedge block structure, which is convenient and reliable. Mechanical or hydraulic adjustment devices can be provided according to user requirements. It is convenient and fast to adjust the discharge port, reducing the adjustment downtime.

The integrated motor base design saves installation space. Motor base mobile design, so that the triangle belt longer service life.

The elastic stop block and rubber damping device are used to replace the rigid anchor connection, effectively absorbing the peak vibration load, thus reducing the mutual impact between the crusher and the foundation, reducing the fatigue damage to the foundation and improving the service life of the crusher.

The motor drives movable jaw assembly do reciprocating motion according to the desired trajectory under the action of belt and pulley. The angle between toggle plate and movable jaw increases when movable jaw moves up and the movable jaw closes to the fixed jaw. The materials are crushed in this process. The angle between toggle plate and movable jaw decreases when movable jaw moves down and movable jaw moves away from fixed jaw under the action of the tension rod and spring, then products after being crushed are discharged from the discharge opening.

| Model | Feeding size(mm) | Max. Feeding size(mm) | Output size(mm) | Capacity (t/h) |

Speed(r/min) | Power(kw) | Overal Dimension (mm) |

| C80 | 520×800 | 420 | 60-150 | 80-290 | 350 | 75 | 2650*1540*1780 |

| C100 | 760×1000 | 650 | 70-200 | 140-400 | 260 | 110 | 3670*2420*24900 |

| C106 | 700×1060 | 600 | 70-200 | 140-420 | 310 | 110 | 3230*2440*2590 |

| C110 | 850×1100 | 720 | 80-200 | 160-550 | 230 | 160 | 3800×2450×2550 |

| C120 | 870×1200 | 740 | 100-200 | 260-650 | 230 | 160 | 3850×2800×3100 |

| C125 | 950×1250 | 800 | 100-250 | 230-760 | 220 | 160 | 4100×2800×3440 |

| C145 | 1100×1450 | 920 | 125-275 | 320-950 | 220 | 200 | 4400×3060×3210 |

| C160 | 1200×1600 | 1020 | 150-300 | 410-1150 | 220 | 250 | 5700×3650×3550 |

| C200 | 1500×2000 | 1200 | 175-300 | 610-1510 | 200 | 400 | 6500×3990×4260 |

| CJ6310 | 630×1000 | 580 | 80-180 | 100-195 | 250 | 75 | 3763×2280×2644 |

| CJ8711 | 870×1100 | 720 | 85-220 | 130-360 | 250 | 110 | 4124×2480×3020 |

| CJ1113 | 1100×1300 | 940 | 120-260 | 360-780 | 220 | 160 | 4863×2762×3489 |

| CJ1216 | 1200×1600 | 1050 | 165-320 | 450-1100 | 220 | 220 | 6700×4040×4465 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13781250944*24-hourWhatsapp/Wechat