It is widely used in crushing and screening combined equipment in metallurgy, coal mine, mineral processing, building materials, chemical industry, abrasive and other industries

Applications: River pebble, granite, basalt, iron ore, limestone, calcite, quartzite, diabase

+86-18638682051*24-hourWhatsapp/Wechat

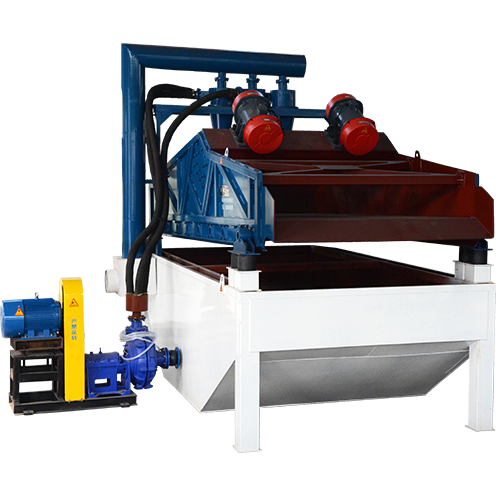

The fine sand recovery machine is widely used for the recovery of fine particle materials such as mud purification, sand and gravel aggregate system of hydropower stations, glass raw material processing system, artificial sand production line and the recovery of coarse slime in coal preparation plants. The loss of fine sand in wet sand production is the main factor to reduce the content of finished sand and stone powder. The use of Baichen fine sand recycling machine not only increases the output, but also solves the problem of low content of stone powder, reduces water and soil pollution, and benefits the country and the people!

The fine sand recovery device can effectively reduce the loss of fine sand and solve the problem of high fineness and low content of finished sand in the artificial sand processing system.

The fine sand recovery system can recover 55% - 80% of the fine particle materials in the total discharge, and can be adjusted at any time. It has incomparable technical and economic advantages compared with other equipment.

The fine particles are fully recovered, reducing the workload of the sedimentation tank and reducing the cleaning cost of the sedimentation tank

The fine sand recovery system reduces the natural stacking time of fine materials and can be directly transported to the market.

At present, most of the existing artificial sand production lines adopt wet production process. Regardless of any form of sand washing machine, its biggest disadvantage is the serious loss of fine sand (particles above 0.16mm), some even more than 20%, which not only loses output, but also seriously affects the grading of sand for artificial sand making, resulting in unreasonable grading and coarse fineness mesh, The product quality of manufactured sand is greatly reduced. Excessive fine sand discharge will also cause environmental pollution. The factory has successfully developed CS series fine sand extraction equipment in view of the above problems such as the loss of fine sand and the inability to treat the mud water for manual sand making, resulting in pollution.

| Model | Power | De-Water Screen | Capacity(m3/h) | |

| Model | Power | |||

| CL-JX3-1022 | 15 | 1022 | 1.5X2 | 50-65 |

| CW-JX3-1022 | 15 | 1022 | 1.5X2 | 60-75 |

| CL-JX6-1230 | 18.5 | 1230 | 2.2X2 | 130-140 |

| CW-JX6-1533 | 22 | 1533 | 2.2X2 | 150-160 |

| CL-JX9-1537 | 22 | 1537 | 3.0X2 | 200-220 |

| CW-JX9-1537 | 30 | 1537 | 3.0X2 | 200-220 |

| CL-JX12-1537 | 37 | 1537 | 3.0X2 | 260-280 |

| CW-JX12-1537 | 37 | 1537 | 3.0X2 | 300-320 |

| CW-JX15-1842 | 45 | 1842 | 3.7X2 | 330-370 |

| CL-JX18-1842 | 44 | 1842 | 3.7X2 | 400-440 |

| CW-JX18-1842 | 60 | 1842 | 3.7X2 | 400-480 |

| CL-JX27-1842 | 66 | 1842 | 3.7X2 | 600-660 |

| CW-JX27-1842 | 90 | 1842 | 3.7X2 | 600-660 |

| CL-JX36-2048 | 88 | 2048 | 5.5X2 | 800-880 |

| CW-JX36-2048 | 120 | 2048 | 5.5X2 | 800-880 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13781250944*24-hourWhatsapp/Wechat