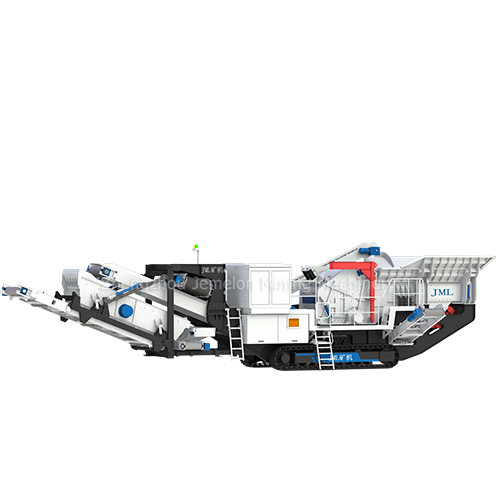

Impact Crawler Mobile Crushing Station is mainly used in hard rock crushing ,aggregate production , outdoor mining crushing,construction waste recycling, cement production and tunnel crushing.

Applications: Impact Crawler Mobile Crushing Station is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate etc. Different final output size could meet your different needs.

+86-18638682051*24-hourWhatsapp/Wechat

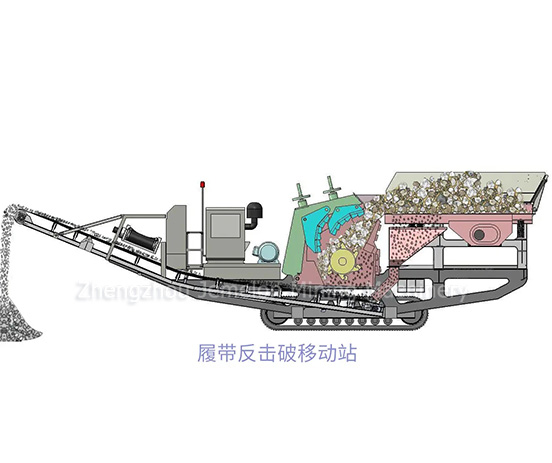

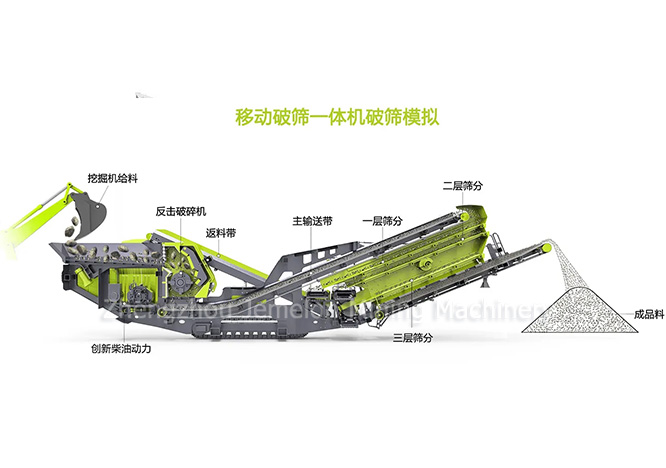

construction waste. The impact crusher equipped with this equipment has not only the advantages of high crushing output, low cost, high versatility and adjustable finished product particle size through the perfect combination of optimized crushing cavity type and high wear-resistant materials; It can also ensure the excellent particle size and cleanliness of the finished product, and meet the high standard requirements of building aggregate. The equipment can be equipped with a vibrating screen to realize the crushing and screening of materials in one station. It can also be combined with other equipment to complete the crushing and screening of materials with high efficiency. It can show large crushing ratio and high production capacity in crushing and recycling of limestone, dolomite, coal mine and other natural materials with medium soft hardness, medium low abrasion, as well as construction solid waste, and produce high-quality finished materials.

Crawler mobile crushing station products have light weight, small volume, especially suitable for narrow site work.

The high-performance counter attacking host designed specially for mobile station is adopted, with high production capacity and good particle shape.

The impact crusher is equipped with hydraulic boom, which is convenient and fast for maintenance and replacement of vulnerable parts, reducing downtime and improving production efficiency.

The famous brand engine set is adopted, with strong power and high fuel economy.

Random attached power group - optimization design.

Intelligent control, PLC intelligent control system, intelligent operation, powerful function.

How Impact Crawler Mobile Crushing Station works? In the mining and quarry industry, mobile impact crusher plant is usually as secondary crushing machine to process rocks or ores from priamry jaw crusher plant. After impact crusher machine crushing, precisely shaped cubical end products is feed to vibrating screen to get different size material, 0-5mm, 5-10mm, 10-20mm, 20-40mm or some other required size. Vibrating screen is designed to be same level with impact crusher. The oversized material from first layer could be fed to impact crusher directly to crush again. Other required size is sent to stock ground by belt conveyor. Compared to stationary stone crusher plant, iIt has good mobility and can extend together with the raw materials site or construction site and has many types of combinations to satisfy the processing needs of different materials.

|

Item |

MC-F250S |

MC-F350S |

|

Capacity(t/h) |

150-300 |

180-400 |

|

Host Type |

F250S |

F350S |

|

Feeding Capacity(t/h) |

500 |

650 |

|

Max Feeding Size(mm)(mm) |

500 |

600 |

|

Discharge Opening Adjustment Range(mm) |

20-150 |

20-150 |

|

Main Belt Conveyor(W*L)(mm) |

1000×9900 |

1200×11000 |

|

Main Engine Power(KW) |

250 |

280 |

|

Overall Power(KW) |

400 |

500 |

|

Transport Size(L*W*H)(mm) |

19000×3600×3800 |

17000×3200×3800 |

|

Total Weight(t) |

60 |

65 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13781250944*24-hourWhatsapp/Wechat