It can screen raw materials of various shapes and sizes, and is applicable to many demanding industries. It is widely used in resource recovery, aggregate production, coal mine production, site waste, construction industry, iron ore screening and other industries

Applications: Crushing of construction waste, screening of rocks, ores, massive road asphalt concrete and other materials

+86-18638682051*24-hourWhatsapp/Wechat

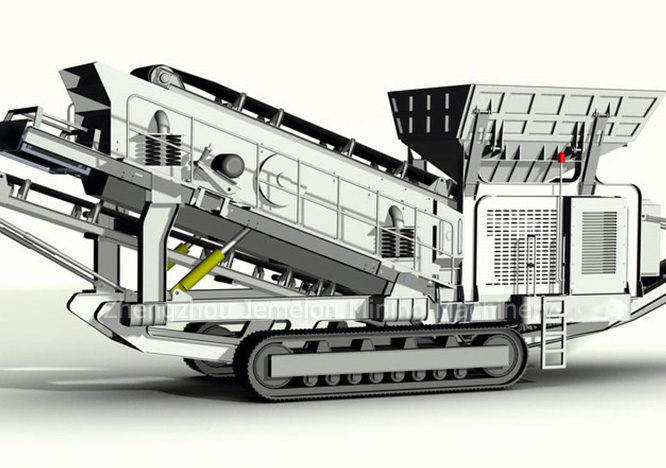

Screening type crawler mobile crushing station equipment is made with advanced design concept and scientific production process. It is effectively used for screening requirements of different materials in combination with adjustable screening angle, amplitude and vibration intensity. With high screening efficiency and large output, it is suitable for various screening operations such as heavy, medium and fine screening. It is widely used in mining, coal, building materials, sand and gravel, metallurgy, chemical industry and other fields. According to the different particle sizes and materials of finished products, we provide customers with a variety of screen surfaces, models and uses of crawler mobile screening equipment.

The transition is convenient and widely used. The crawler is mobile, and it is applicable to a wide range of working conditions. The transition is very convenient. Under any terrain conditions, this equipment can reach any position on the work site and be put into production quickly.

The equipment has a large capacity receiving hopper, which can effectively buffer materials and ensure continuous and stable material in put.

The whole machine adopts hydraulic folding technology, and the transportation status and working status can be quickly switched. Reduce the time waste of transit transportation.

The high strength steel frame structure is adopted to improve the service life and strength of the equipment, with extraordinary durability.

The compact structure design enables the equipment to perfectly adapt to various working conditions and production sites.

The number of screen faces is optional, which can be customized flexibly according to different sizes and types of finished products.

The motor makes the eccentric block of the vibration exciter rotate at high speed through the triangular belt. The running eccentric block produces a large centrifugal force, which excites the screen box to produce a circular motion of a certain amplitude. The materials on the screen are continuously thrown by the impulse transmitted by the screen box on the inclined screen surface. During the process of meeting the material and the screen surface, the particles smaller than the screen hole are penetrated through the screen, so as to achieve classification.

| Item | Capacity(t/h) | Screen model | Sieve size(mm) | Main belt conveyor(W*L)(mm) | Over power(kw) | Transport size(L*W*H)(mm) | Overal Quality(t) |

| MC-S6018 | 85-300 | YZS1860 | 1800-6000 | 1000-11000 | 50 | 14500*3500*3850 | 33 |

| MC-S7020 | 100-350 | YZS2070 | 2000-7000 | 1200-11000 | 65 | 14500*3800*3850 | 45 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13781250944*24-hourWhatsapp/Wechat