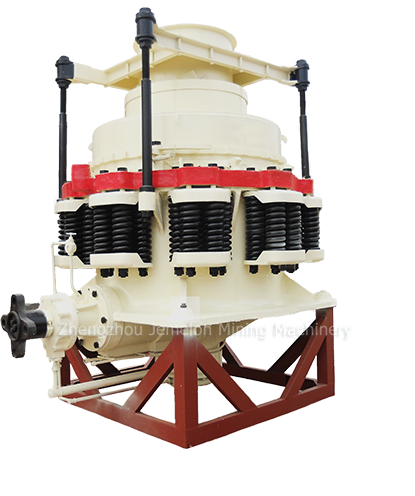

PY series cone crusher is widely used in sand quarry, mining, coal mining, concrete mixing plant, dry powder mortar, power plant desulfurization and quartz sand.

Applications: Basalt, granite, river stone and all kinds of ores and rocks with medium and above hardness.

+86-18638682051*24-hourWhatsapp/Wechat

PY series spring cone crusher is the first cone crusher, which is based on absorbing the internationally advanced technique; It has been used in the secondary and tertiary crushing. The spring insurance system is the overload protection device; The sealed form is dry oil or water; According to the crushed ore use, it is divided into three types: the standard type; the medium type and the short head type.

The movable cone operates conveniently, the crushing and discharging process works alternately and continuously; there is a parallel gap between the movable and fixed cone, which makes the final product fine cubic shape.

Type of the crushing chamber is decided by the application of the ores. Standard type is for PYB (secondary crush); middle type is for PYZ (tertiary crush); short-head type is for PYD (Ultra fine crush).

PY series cone crusher adopts the dry oil or water as the sealed form, which makes the dust be out of the main unit. It ensures the clearance of the lubrication oil, which extend the lifespan of sliding bearing and thrust ball bearing. Therefore, the machine operates reliably.

The working portions of spring cone crusher are cones, the fixed cone and movable cone. In the area of the movable cone moving close to the fixed cone, the ores will be squeezed, knocked and crooked, this area is the crushing chamber; when the movable cone deviate from the fixed cone, the crushed material will discharge, this is the discharging port. During operation, the motor drives the eccentric shaft shell to turn around through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed and crooked and crushed.

| Model |

The diameter of crushing head bottom(mm) |

Max. Feeding size(mm) |

Adjusting range (mm) |

Capacity (t/h) |

Power (KW) |

Speed of Eccentric Shaft (r/min) |

Weight (t) |

Overall dimension (mm) |

| PYB600 | 600 | 75 | 12-25 | 40 | 30 | 356 | 5 | 2234×1370×1675 |

| PYZ600 | 600 | 35 | 3-13 | 5-23 | 30 | 356 | 5.3 | 2234×1370×1675 |

| PYB900 | 900 | 115 | 15-50 | 50-90 | 55 | 333 | 11.2 | 2692×1640×2350 |

| PYZ900 | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 11.2 | 2692×1640×2350 |

| PYD900 | 900 | 50 | 3-13 | 15-50 | 55 | 333 | 11.3 | 2692×1640×2350 |

| PYB1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 300 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 25 | 2790×1878×2844 |

| PYD1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 300 | 25.3 | 2790×1878×2844 |

| PYB1750 | 1750 | 215 | 25-50 | 280-480 | 160 | 245 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 1750 | 185 | 10-30 | 115-320 | 160 | 245 | 50.3 | 3910×2894×3809 |

| PYD1750 | 1750 | 85 | 5-13 | 75-230 | 160 | 245 | 50.2 | 3910×2894×3809 |

| PYB2200 | 2200 | 300 | 30-60 | 490-750 | 260-280 | 220 | 80 | 4622×3302×4470 |

| PYZ2200 | 2200 | 230 | 10-30 | 200-580 | 260-280 | 220 | 80 | 4622×3302×4470 |

| PYD2200 | 2200 | 100 | 5-15 | 120-340 | 260-280 | 220 | 81.4 | 4622×3302×4470 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13781250944*24-hourWhatsapp/Wechat